Stock Tank Full Sensor Without Trenching Miles Of Wire

Today, I want to tell you about our Wireless Tank Full System. I’ll give you an overview of how the system performs, the applications and then I’ll unbox it. We’re going to head out in the field and get one installed and show you exactly how it operates. We find when we’re running a wire more than about 200, 250 feet, then it really starts to make sense to look at the wireless option.

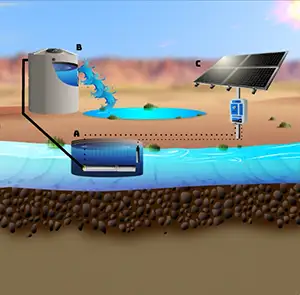

With the wireless system, we simply put the transmitter at the tank. That monitors the tank level and sends a signal back to the receiver that we locate near the pump. That will tell the pump when to turn on and off. Also, if you’re going to locate a receiver inside a building, the nice thing is, we have an antenna with about six feet of wire so you can locate the controller inside of your pump house. Then you can run the antenna outside, because the signal is not able to go through buildings, doors or other concrete structures like that.

So with a basic understanding of the system, let’s grab some hardware. I’ll show you what comes in the kit and go over all the major components. With this system, we have four basic models. We have the daytime only operation, which is great for solar pumps because without batteries they’re only going to be operating during the day. The wireless system will only operate during the day.

If you have AC hooked up or you have batteries, then this is our 24 hour system. So this includes a battery, which I’ll show you in a second. That allows it to operate 24 hours a day and even tells the pump to turn on and turn off signals at night. Then we have our AC versions. With the AC version, the transmitter runs on solar and has a battery, but the receiver, since we’re running an AC pump, operates off of AC. We have 2 versions of that. We have a 120V version and a 240v version both rated to 30 amps, which can operate a pretty large pump. We’re looking at around a 3HP pump.

So let’s dive into our 24 hour operation kit. While I’m doing this, I’ll explain some of the differences between the different units. The first unit we’re going to pull out of our box here is our transmitter unit. You can see on the front here is our solar panel. On the back here, we have two more components. We have our circuit board transmitter here, and then we have our battery. The battery is what makes it a 24 hour operation. So the only difference between the daytime only and the 24 hour operation is the addition of this lead-acid battery, which provides us around four and a half days of runtime without any sunlight. If any time during that we get a little bit of sunlight, then we can quickly start to recharge that battery. Next, we’re going to take a look at our receiver. So let’s pull that out of the box.

It looks very similar. On the front here, we have our solar panel and on the back here we have our receiver and our battery. We also have our mount, which is to allow for simple mounting wherever we need to put this solar panel and equipment. You’ll see they look very similar.

The only difference between these two transmitting and receiving units is where the wires are hooked in. So it’s all pretty wired. You’re not going to have to go in this box and switch the wires around. But if you need to custom configure, we have some normally open contacts, some normally closed contacts. If you need to make those changes, we have our user manual. It’ll talk about swapping the wires over for your specific application. We pre-wire it for about 90% of the applications out there, and so the other 10%, you might have to swap a wire or two in order to get it to work for your specific controller.

There’s a few more accessories in the box. We have our user manual. That’s going to go through all of the installation and setup, and it’s very simple. Basically, mount your transmitter, mount your receiver, hook up a couple of wires and this system’s up and running. We also have our two antennas and these are attached to the bottom of our transmitter and receiver. It’s very nice because you can put your transmitter or receiver down low and then put your antenna up high.The higher you go with the antenna, the better the line of sight and the longer distance you’re going to get from this system.

Then we have a couple other parts in the box. We have our self-drilling screws. The self-drilling screws are going to be used to mount our solar panels. On the bottom of this solar panel bracket, there are two holes. We put two screws in and that can go into wood or metal. If you’re going into concrete, you probably want to get some masonry screws. Basically you can mount it wherever you need to go!

Next we have our shrink tube kit. The shrink tube kit is going to be used for two parts. First, it’s going to be used to extend our sensor. So depending on the exact installation, if you need to go a little bit further than your sensor, you can use this kit in order to extend it and attach it to our sensor inputs here, which is going into our transmitter. There’s two extra shrink tubes. You might not need them, but if you do need to extend your wire going from your receiver to your pump controller, then you can extend this wire out using the other shrink tube kit.

So the last item is going to depend on the exact system you’re using based on your application. So for the daytime only operation and the 24 hour system, those in general are going to be used with a solar pump or a VFD and a soft start. Those are not going to be as concerned with the amount of times we start and stop the pump because the soft start prevents it from overheating. If we’re using one of those systems, then we’re going to be using a stainless steel probe.

This wires directly into our transmitter and sits in the top of the tank. Any time the water level drops below the probe, it’s going to turn on the pump and fill the tank right back up. if you’re using our 120 volt or 240 volt AC system, then it’s going to come with a more traditional float switch. With the float switch, you can control the throw and so we can prevent the pump from cycling too many times by adjusting that throw.

So when the float is down, it’s going to send a signal to our transmitter to turn on the pump. Then when the water level rises up, it’s going to tell the pump to turn off. If you’re using your AC system, you’re not going to have a receiver that looks like this. Down below here we have our AC receiver. This is actually our 120 volt version. And if we open up this box, we can see the same type of controller here with a couple extra components.

First of all, we have our AC to DC converter, which takes the AC power that’s going at the pump and converts it to DC to run our electronics here. We also have a contactor. So for the 120 volt version of the 240 volt version, the only difference here is the contactor we’re using. Both of those contactors are rated to 30 amps of operation. If you’re using 120 volt, it’ll be a 120 volt contactor and if you’re pumped to 40 volts, then it’ll be a 240 volt contactor. Today we’re going to use our stainless steel probe because we’re installing this on our solar-powered universal controller and that comes with our RPS200, RPS400, and RPS800. It also comes with some of our surface transfer pumps. It’s a very common controller. It also comes with our RPS400V, RPS800V, and our transfer pumps.

The first step of this is splicing the wire from the sensor to the transmitter. Then we’ll bring everything outside, install our tank and get our receiver hooked up to our universal pump controller. Within about 10 minutes, we’re going to have the entire system operating.

For this installation, we’re only going to need a couple of tools. First of all, we’re going to need wire strippers which are here on our pliers, and a crimper. I like the all in one tool. It makes it much easier and quicker to use.

We’re going to need a heat source. In this case, we have a little butane torch. We can also use a lighter in order to do our shrink tubing and seal everything down tight. Our screwdriver for the terminals on our controller. Then we also have our little driver. You could also use an impact, a drill, anything in order to put in those self drilling screws.

So those are the basic tools we need. We’re going to quickly do our splice here indoors. It’s much easier always to work inside and do our splicing. So with the transmitter, there are only two wires. We’re just going to need to take our sensor here and splice that onto the wire going into our transmitter side. For this next splice, we want to make sure our shrink tubing goes all the way onto our wire. In this case, we’re going to strip back our outer jacketing a little bit more. With the stainless steel probe, polarity does not matter. It doesn’t matter which wire I hook from the sensor into the transmitter here. If we’re using the float valve, then it does matter. The instruction book tells you exactly which wires to hook up depending on the operation of your pump.

So, our two crimps are complete. Now this is adhesive-lined shrink tubing, so we’re going to evenly heat it down, trying not to use our torch to burn anything. If you see a little smoke, then you need to back off and let it cool a little bit until the shrink tubing cools down. Then out of each side, we’re going to see a little bit of that hot melt adhesive squeeze out of the end.

So there we have it. We have it all shrunk down. You see in the middle, it got a little hot there and it started to smoke. So I backed off, moved to another section, allowed that to cool, and then went back later. If you’re going to leave this outdoors, I might add a little electrical tape wrapped around there to add some more physical strength so if this gets pulled on, it’s going to put a load on the crimps and we’d rather have that go on the insulation. So a couple of wraps of electrical tape and we’ll get that sealed up. If t’s inside, you can probably leave it just like this and be fine.

We’re going to head out to our tank and get that system running. First of all, we’re going to install our receiver. We ship the unit powered down, so the first thing we want to do is to plug our solar panel into our receiver. We will give you a little bit of extra wire in case you want to disassemble this and install your receiver inside, say in your pump house, and then locate your solar panel outside.

There’s a little bit of wire, so you go through a wall or other structure to move that inside. But otherwise we just tuck it right back behind our bracket here. If you have the 24 hour version, you’re going to have this battery up here. We remove the battery cover and we attach our ground wire up.

So there we have it! The system is powered up and you can tell because the power light is flashing. By default, our tank full light is on. Now, if I was going to mount this permanently here, I’d be installing a post, probably a wooden post into the ground, and then I’d screw it right into there. We really don’t have to be too careful about that because it is oversized for what we need here. It just needs to be in a bit of light.

For now, I’m going to set this down to the side and then we’re going to wire our controller input into our universal controller. We have the RPS800. You can tell because there’s eight solar panels behind me. That’s feeding into our RPS universal controller and then going down into our well, pumping the water. We’re going to hook this signal wire into our tank full input on this controller. On your specific controller, if you have a different type, it might be an enable/disable. On our pro controller, it’s the little pigtail.

Whichever controller you have, it’s going to be the “tank full” or the “enable/disable input”.Remove the cover, put in the wires and then we’ll be done with the receiver and the pump side.

With our sensor wire installed, we’re going to install our antenna. Super simple. Take it out of the bag and attach the antenna to the magnetic base. Then again, once it’s going to be mounted permanently on a post, I’m going to go about five feet tall with it. Our tank is located way over there so when I permanently install my receiver, I’m going to have that wooden post in there. Then I’ll put this up on top of my wooden post. For now, it’s going to be located on top of my controller and I’ll come back and place a more permanent mount later.

So, we’re over here at our tank. For the short term, we’re going to mount our transmitter here on this small pallet. Once we get our pole mounted, we’re going to move it over to our post and get it mounted there. I’ve hooked up the battery, I’ve hooked up the solar panel, and now I’m going to use the self-drilling bolts to go down into the wood. With our system mounted, it’s time to install our sensor.

The operation is super simple here. Right now, the water level is right about here in the tank and when that water level drops, then it’s going to send a signal from the transmitter back to the receiver saying the tank is empty and we need to turn on the pump in order to fill the tank back up. The tank full light is normally on when the tank is full, but when it gets that signal, then on both the transmitter and receiver, the tank full light is going to go out and then you’re going to hear the pump start running.

In order to artificially simulate that, I can lift up the sensor a little bit and that’s sending a signal right now over to the controller. The light’s turned off and now you can see the pump turned on and it’s flowing out of our garden hose. So now that pump is pumping. So in order to simulate the tank getting full, I’m going to lower the sensor a little bit. I can feel it back in the water, that’s like the level rising in the tank. Now, the transmitter sends the signal back to the receiver saying the tank is full, it’s time to shut off. There we have the tank, full light just turns back on and the pump shuts down. So there we have it. With about 10 minutes of work, we have our wireless system up and running, sending that signal from our tank back to our controller, controlling that pump and making a fully automated on and off system to keep your tank full.