DIY Solar Pump Sleeves / Pump Shrouds

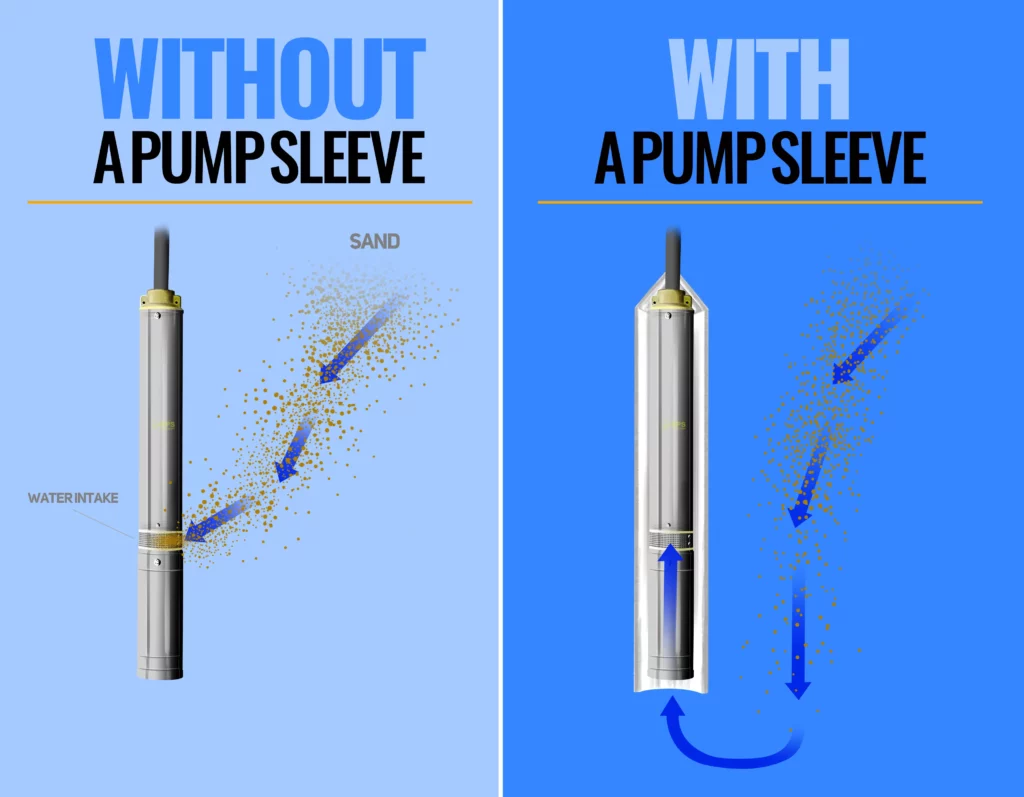

DIY Pump Sleeves help encourage water flow cooling around your pump’s motor when horizontal, and in sandy wells, encourages sand to fall down safely past the pump intake. We use the term ‘pump sleeves’ but it’s also commonly called a ‘flow sleeve’, ‘flow inducer’, and ‘pump shroud’.

While DC Brushless Motors used in RPS Solar Pumps do not generate nearly the heat of induction motors, cooling of the lower motor end is still important. When pumping from larger water sources, such as above ground tanks, cisterns, ponds, or in much larger diameter wells, heat dissipation is a bigger issue as water’s path of least resistance is flowing directly into the middle intake of the pump, and not flowing around the pump’s motor. In these situations, a pump sleeve is highly recommenced.

In the case of sandy wells or rusty casing wells, pump sleeves are also recommended if the well is top feeding (water flows in from above), or when a pump is placed below the wells perforations/screens so that the sand is able to fall down past the pump and get pulled into the pump’s intake.

A common DIY Pump Sleeve we recommend is simply a piece of 3″ or 4″ PVC (depending on RPS Pump Model and Well Casing Size) and with a reducing coupling at the top that prevents water from flowing into the middle pump intake, and instead encourages it to flow from the bottom, up around the motor to cool it before entering the intake. Most recommend cutting the PVC about a foot longer than your assembled pump. PVC pipe with thinner walls is fine. A rubber reducing coupling with hose clamps can be used to fasten around the wire and plumbing at the top, expanding to hose clamp on the PVC pipe to hold it in position and prevent it from slipping down and off the pump.