Joshua’s Freeze Proof Pressure System – RPS Solar Pump Pioneers

Pennsylvania

“Joshua’s Freeze Proof Pressure System”

Installed:

RPS 400

48V Deep Cycle Gel Battery Bank

RPS Top-of-Pole Solar Panel Mount Kit

Pitless Adapter Well Head Assembly

Check Valve and Threaded Nipple

System Specs at a Glance

Well Depth: 500 feet

Static Water Level: 45 feet

Additional Vertical Lift: 10 feet

Horizontal Distance: 1,700 feet

Casing Diameter: 8’’

Pressure Tank set to 30/50 psi

Joshua’s Farm

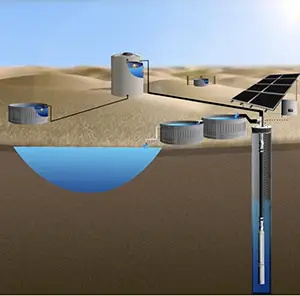

We’re in Pennsylvania, we definitely have season changes. We can see 100 degree weather in the summer and we can see 0 degree weather in the winter. We have 70 pairs that we run across these two farms and doing all our own back-grounding and stocking. Everything is out all the time even in extreme temperatures so I needed to be able to supply water no matter when. There are no barns, and the cows are outside all the time, in all honesty they do better out there anyways. This was a nice addition to getting water where we don’t have it and we can expand going forward this way fairly affordably. We’ve evolved into using a management practice in intensive grazing. We’re kind of above the fescue belt, our pastures are pretty heavily fescued with orchard grass we have some rolling hills and the cows can walk up one hill and down the other and we’ll have water for them as they go across.

Working with NRCS

It started with NRCS, I wanted to do a solar project for a well out in the middle of this farm that’s not very accessible. NRCS has done them before where they pump into a holding tank and then the holding tank gravity feeds out. I said what about the tank freezing? Well, they said you can’t use it during the winter months, and I said that’s no good I want to be able to use it all the time. So, they said you’ll have to use it with a pressure tank and bury it. I couldn’t get a plumber to do it, I don’t know why, so I said we’ll tackle it ourselves! In all honesty kudos to RPS because I read that book front to back and the YouTube videos were a big help, I wouldn’t have been able to do it without those support materials.

NRCS was trying to learn a lot from what I was doing. We’re doing some experiments on grazing, animal soil impact and I think part of this is striking their interest for isolated areas that it’s hard to get water to. The cool thing with this project, this is through a private non-profit called Capital RC&D, they use NRCS technicians to help with project guidance.

Find your local NRCS Service Center here! Learn more about how RPS works with NRCS!

System Design

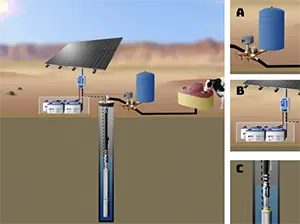

On another property they have what’s called a punched out well. At some point around here they had hand dug wells and at some point they decided to “punch” them out and put in a casing. They built a cinder block box around the well and the pressure tank, so I can’t say that it was originally my idea i just took the concept from them. Because my well is so isolated away from any kind of structure I didn’t want a structure that had to be insulated. NRCS talked about a couple different examples, like burying the tanks, but I wanted something that was a little more solid. There are some concrete pre-cast businesses 60 miles away and I called them. I was looking for a manhole riser that came out of the ground and was square, and then after talking with them a couple different times they came up with the thing that I bought, it’s called a well observation pit. For the money, it was $340 for that whole concrete thing, really not that big of a deal, was pretty affordable. Everything is sitting on a couple of cinder blocks just in case the concrete observation pit floods.

We have the RPS 400, so we have 4 solar panels. I talked with Katelyn three or four times before I actually bought, she figured out the head that we have to size the pump. She told me the batteries were basically a must if I wanted to use it in the winter on a pressurized system, so I bought the 48V battery bank, I bought a little big bigger than what we actually need, currently I thought it was better to have a little more water on daily basis in case we wanted to expand or our cow numbers go up. We really should keep the batteries out of the weather and I just ran the lines down into the pit. We have a pressure tank set at 30/50 and 1 inch diameter pipeline going 1,700 feet across the farm. Every 300 feet I have a quick connect coupler buried in the ground that connects to a trough, so every 300 feet I have water.

Install

The biggest problem I had was figuring where I was going to put the panels and where I was going to put the pit in relation to the well. All I had when I started was the well, there was nothing there. I had to put a pitless in, I had to dig the ditch, I had to excavate where the pit was going to go. Once I got the book and figured out where the wiring was going to run, I didn’t want to put the control panel in the pit. I ran 1 inch water line, 160 psi black pipe as conduit that I buried until it ran up the side of the solar panels into the control box. So there’s actually 2 sets of conduit there one that runs to the well and one that runs to the observation pit.

The only other problem I had, and it was my fault, RPS offers the reverse action pressure switch the I didn’t originally get. Before I got the manual I told Katelyn that I’ll get the pressure switch locally. I just happened to read the book again and it said reverse action pressure switch, and I wondered what the difference is between that and a regular pressure switch. So I did some research and went into a local plumbing store, but they had no idea what I was talking about. Again, I called Katelyn, she sent me one out and I has one in 5 days. The local place was going to be two weeks before they could get one. So again kudos to RPS they got the whole way across the county in a couple days. Makes sense once you do it, just works in reverse as a sensor.

I hooked everything up, watched the video on whether the batteries have to be in series or parallel, I was a little worried wiring that wrong because I didn’t want to cook the box. Everything just jived, I had it hooked up and said “ no way this thing works on the first try” and it worked, turned it on built the pressure to 50 PSI and shut off. I couldn’t believe, to be honest with you, that it worked on the first try.

I had 70 pairs and 30 stockers for the couple days after I finished and it didn’t miss a lick.