Joe’s Windmill Replacement – RPS Solar Pump Pioneers – Episode #2

Texas

Texas

Installed

System Specs at a Glance

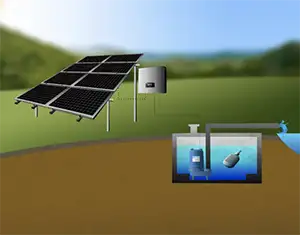

2,000 Gallon Storage Tank + 11,000 Gallon Storage Tank

70′ Static Water Level

100′ Set Depth on 3/4″ Poly Pipe, 12-2+G Wire

Joe’s Farm

We’ve got 40 acres of coastal bermuda grass and last year we bailed with one cutting 202 bales, this year with one cutting we got 212 bales, and its horse quality. We may do a second cutting this summer in a few weeks, if so we’ll be able to get another 40%,or 75 to 80 more bales out of it. The pump works well and takes care of stock and swimming pool but does not do any watering for the hay fields.

System Set Up

Right at the pump, and next to the 2,000 gallon tank, we have a water trough. But that goes down the hill to a big cistern, which holds almost 11,000 gallons. It’s been keeping that 2,000 gallon tank and 11,000 gallon tank down the hill all full of water. And that little pump can fill it up in two days and that’s great in the summertime. The big cistern down the hill is fixed up so the kids can go swimming. Also, whenever we mix poisons for the hayfield we can get water right there instead of having to go back 1 ½ miles to the house. We mix up poisons to kill nightshade or any other kind of things in the coastal bermudagrass patch.

Original Pump Install

The bucket test was done back at the shop, I had the little power supply, I would recommend that to anybody as an extra help. I was powering the pump with that rather than the arrays and it made me smile when I saw that water coming out.

No problems splicing the wires, I’ve done that kind of stuff all my life. I was glad that the we had the heat shrink right there, RPS supplied everything we needed.

Mounting Solar Panels

The problem with the windmill was that it wasn’t facing south, if it had been facing south it would have made the array mount much easier. But I had to put that thing on cockeyed about 45 degrees off from the face of one of the windmill legs. I built that mount in the shop, made it out of the material that you use for electrical installs of runs and boxes, pretty heavy metal. It worked well and I did not weld one piece and I got it to where I could get it piece by piece on the windmill. It took a little time but it works fine. I have the controller mounted underneath one of the arrays so it doesn’t get rained on. Set it up high enough that the cows can’t hit the bottom of the array, in fact I can walk underneath.

Replacing His Helical Rotor Mechanism

I have a RPS 200 and the thing had pumped for about a year and half without any trouble and then it quit pumpin’. I was afraid that it was the controller, but after talking with your engineer there for some bit of time he helped me to understand that it was more than likely that the pump itself wasn’t turning. I’m 80, and my grandson is about 25, so we had a 25 year old a 50 year old and an 80 year old in and out of that well. My son and I installed it the first time, but when we pulled it to fix the rotor the three of us did it. Two could do it, but just makes it easier if you’ve got one pulling the rope and the other giving some guidance as the pump comes out. My son, grandson and I started on Friday morning, we pulled the whole thing out of the ground, it was on 100 feet of flexible pipe. My grandson pulled the rope up, my son pushed the column over the windmill and I took the well head off, just to kept it out of the way. Laid the pump on the tailgate of the pickup and took it apart. There’s only 6 bolts that you have to work with plus two screws that hold the screen on. The replacement piece that RPS sent had all that was necessary including an allen wrench, which I appreciate. Anyhow, it didn’t take but 15 minutes to open the pump up, put the new one in and put the pump back together. We were finished by 10 AM, so it was less than 2 hours between the time we started, fixed it and put it back in the well.

Compared to all the wells that I have pulled in my life that has been by far the easiest one. Windmills, submersibles pumps and all that just are a pain compared to what this little pump, I am so thankful for it. I didn’t really run into any real problems. I did not test the pump before we put it back in. We put it in on faith hoping that it would go ahead and run and it did! So I’m pleased about that. I needed to clean the array off, birds have been up there and decorated the face of the arrays. The only thing I wish i knew was why the rotor quit, it was not full of sand, it’s hard water here but it did not have any kind of limestone caked on it. The only thing I could see is sulfur, guessing we’ll have to replace that every 2 years, just the way it is.