To ensure that we send you the proper size well cap seal, we’ll need your well casing diameter. Well cap sizes are based on the INSIDE casing diameter. To measure this you’ll need a measuring tape and a string/rope.

If your well cap is off

Simply measure the inside diameter of the casing as accurately as you can and let us know this measurement and the material of your casing (steel or PVC).

If your well cap is on

Take a piece of string or rope and wrap it all the way around your well casing (not the well cap!) and mark the length. Next, place the string flat with same tension and measure it—this is the circumference of your well casing. Divide this number by 3.14 to get your outside diameter. Subtract 1/2″ to get your inner diameter. Let us know what this number is and the material of your casing (steel or PVC).

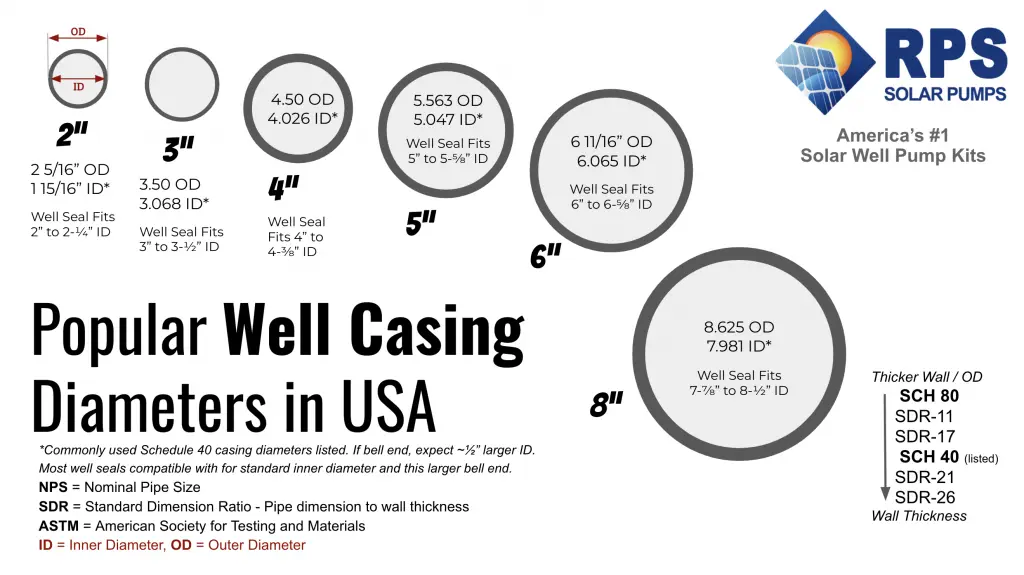

*Commonly used Schedule 40 casing diameters listed. If bell end, expect ~½” larger ID. Most well seals compatible with for standard inner diameter and this larger bell end.

NPS = Nominal Pipe Size

SDR = Standard Dimension Ratio – Pipe dimension to wall thickness

ASTM = American Society for Testing and Materials

ID = Inner Diameter, OD = Outer Diameter

Larger well seals do exist, but most customers fabricate a metal slab with a 4” hole cut out for a standard well seal to be used on larger well casings or cistern openings.

RPS “Turnkey Kits” come with your choice of a 2”, 3”, 4”, 5”, 6” or 8” stainless steel well seal along with all the plumbing, wiring, mounting etc. to install your solar well pump.