Can I Use Solar Power to Water My Cattle?

Solar power is quickly becoming the fastest growing energy source in America, due to increases in efficiency, government benefits and a desire to reduce dependence on our frayed energy grid. To cattlemen, the key benefit of solar power is going to be energy independence; producing power on your own without having to grid-tie is an incredibly freeing feeling. No more power bills, no more meters, just straight energy from the sun. So in short, yes, you most certainly can use solar power for cattle watering, as evidenced by the livestock pumps we’ve designed explicitly with that in mind! Let’s chat through the pros and ‘cons’ of solar pumping, as well as a few common cattle use cases where solar pumps can come in handy.

Some obvious advantages of solar pumps include no monthly fees, no expensive bills for laying down grid lines, and some nice government tax cuts if you know where to look. Combine that with RPS Solar Pumps’ unique approach to sales and servicing, including our Rapid Replace program and easy to understand warranty, and you’ll be surprised how quickly the benefits add up. Due to the plug-and-play nature of our kits, installation is incredibly simple, and for any questions you do have our customer service team is just a text away.

So then, what are the downsides to these pumps, if any? While we don’t think of these ‘cons’ as negatives, (more-so considerations) it’s important to be aware that solar pumps and grid-tied pumps are different. For one, these kits run off of the sun; they don’t pump at night unless there’s some other form of energy powering them. Sadly there is no moon power or star power, at least not yet! Now, solar power can be stored in batteries, which can then be used at a later time in the evening or in low-light conditions. But batteries are inherently less efficient than direct-drive pumping, and you’re never going to be able to pump 24/7 off of them outside of some very specific use cases. That’s why we recommend oversizing your pump kit a little bit past your estimated needs, making use of larger storage tanks to hold water for cattle. If you’re really keen on other methods of backup we also do have options for generator or AC hookups.

Besides that, the main thing folks can get hung up on is price. The reality is that an equivalently sized solar pump compared to an AC pump is going to cost more. There is more specialized equipment in our solar kits compared to our AC kits, so that makes sense. What’s important to consider though is whether or not the monthly cost savings of not having to run power or city water outweigh the initial cost of the solar kit. For ranchers who often don’t even have grid-power where they want to pump, the answer is a resounding YES! So let’s chat a little more in detail about specific cattle watering examples, and how a solar pump can be used in each setting.

Example 1: Samuel has a shallow 50’ well (water at 25’) with a windmill that keeps on breaking down. He’s finally considering replacing his windmill with a solar pump, but doesn’t know if there are any pumps that can fit down a 3” well. He’s also worried that his 50 head of cattle will need too high a volume of water for a solar pump to keep up with. What would we suggest?

Samuel is in luck, seeing as we have some of the very best 2” Diameter solar pumps on the market. While technically these are “2.01” OD, that’s plenty of room to work with. At a 25’ Static Water Level, our RPS 200N will do about 5.5 Gallons Per Minute (GPM), or in a conservative six hours of pumping a day, about 2,000 Gallons Per Day (GPD). Estimates of cattle volume needs vary, but at about 20-30 GPD per cow, that’s going to be about 1,000-1,500 GPD for 50 head. This is going to be a great pump, seeing as even with conservative estimates the pump will do more than the maximum needs of Samuel’s cattle. He might want to pair a 2” pump with a 2P Mounting Kit; alternatively he could also mount our solar panels right on his windmill, as so many of our customers enjoy doing.

Example 2: Dominique is designing a new rotational grazing operation, and would like to pump from one 100’ well (50’ SWL) to four different cattle tanks, for a total of 150 head of cattle. He’s not sure what sort of stop-start mechanism we have for our solar pumps, is there any solution we have for him to make sure his tanks aren’t overflowing all the time?

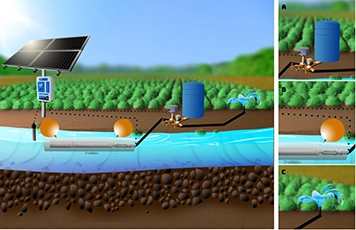

While we normally pair our solar pump kits with a single tank-off sensor, if you’re wanting to plumb to multiple tanks that’s just not going to work. Instead, we’ll need a pressure assembly consisting of a pressure switch, four cattle floats, and a couple of check valves for good measure to prevent backflow in the plumbing system. Assuming frictional losses are minimal due to wide piping diameters*, we are looking for a pump that can pump up 50’ of head, doing at least 4,500 GPD. At these values we would recommend an RPS 800V kit, that at 6 hours of daily pumping is doing about 5,200 GPD (14.5 GPM). In this design, as the pump runs to all four cattle tanks, eventually the cattle float will shut off a valve, preventing overflow. Once all four cattle floats are shut, pressure will build in the system, until the pressure switch installed by the pump controller sends a signal to shut off the pump. This is a great system for fairly short runs over flat ground, but in areas with high elevation gains, pressure switches don’t always work properly. Let’s look at one more example of a cattle operation using some highly specialized equipment:

Example 3: Georgie is wanting to pump from a 300’ well (200’ SWL) up 500’ in elevation to a tank for 30 cattle. There is a ½ mile run from the wellhead to the tank. He wants to make sure there’s no overflow, doesn’t want to run wire for a tank-off function, and doesn’t trust a pressure switch to work well in these conditions. What else can we offer him?

First of all, we are looking for a pump that can handle a total of 700’ of lift, pumping about 900 GPD. Those values align well with our 2HP PRO 2000D pump, running off of 8x370W panels. To prevent excessive frictional losses, we would recommend at least 1.25” piping. The most important part of the installation, however, is going to be the use of our wireless water tank transmitter. As long as there is line-of-sight between our solar-powered transmitter (at the tank side) and receiver (at the controller side by the wellhead), the off-grid tank sensor probe we send will be able to transmit a tank-full signal to the pump controller, shutting off the pump. We are very proud of this sensor, seeing as it is one of the first of its kind, and have tested ranges of up to 2.5 miles, so a ½ mile run shouldn’t be any issue at all!

If you have more questions about solar power, cattle designs, or applying for government funding, we would love to help. Our clientele include farmers, ranchers, off-grid home owners and more! The values that connect all of us is our shared passion for off-grid energy systems, a DIY work-ethic, and a desire to live and work to a high standard. We hope you’ll join us in that mission; we’re easy to reach over the phone or through text at 888-637-4493, or through email at [email protected]. Please feel free to get in contact with us, but until then have a great day!

*Frictional losses occur over long runs of piping, when piping diameter is narrow and pumping volumes are high. For runs over a couple hundred feet, your RPS technician will run through the relevant calculations, and suggest a piping diameter that reduces the relevant frictional losses.